What is schedule 40 carbon steel pipe ?

- Share

- Issue Time

- Apr 19,2024

Summary

The term "schedule" refers to the wall thickness of the pipe and is denoted by a numerical value. The thickness of schedule 40 pipe varies depending on the nominal size (diameter) of the pipe. For example, a 2-inch schedule 40 pipe typically has a wall thickness of 0.154 inches (3.91 mm).

Schedule 40 carbon steel pipe is a type of steel pipe characterized by its specific thickness and pressure rating. Here's how you can describe it:

Material: Schedule 40 carbon steel pipe is made from carbon steel. Carbon steel is known for its strength and durability, making it suitable for various industrial applications.

Schedule: The term "schedule" refers to the wall thickness of the pipe and is denoted by a numerical value. In the case of schedule 40 pipe, the wall thickness is relatively standard and thicker compared to lower schedules, providing increased strength and resistance to internal pressure.

Thickness: Schedule 40 carbon steel pipe has a specific wall thickness defined by industry standards. The thickness of schedule 40 pipe varies depending on the nominal size (diameter) of the pipe. For example, a 2-inch schedule 40 pipe typically has a wall thickness of 0.154 inches (3.91 mm).

Pressure Rating: Schedule 40 carbon steel pipe is designed to withstand a certain amount of internal pressure. The pressure rating is typically expressed in pounds per square inch (psi) and varies depending on factors such as the pipe size and material properties. Schedule 40 pipe is commonly rated for medium pressure applications.

Applications: Schedule 40 carbon steel pipe is used in a wide range of applications across various industries, including process piping, construction, and infrastructure. It is suitable for conveying fluids, gases, and solids in both commercial and industrial settings.

Joining Methods: Schedule 40 carbon steel pipe can be joined using various methods, including welding, threading, and grooving. Welding is a common method for permanently joining sections of pipe, while threading and grooving allow for easier assembly and disassembly using threaded connections or mechanical couplings.

Corrosion Resistance: Carbon steel pipe, including schedule 40 pipe, may be susceptible to corrosion, especially in environments with high moisture or chemical exposure. Proper coating or lining can be applied to enhance corrosion resistance and extend the service life of the pipe in corrosive environments.

Nominal size | DN | Outside diameter | Outside diameter | SCHEDULE 40 | |

|

Wall thickness

|

Wall thickness | ||||

|

[inch]

|

[inch]

|

[mm]

|

[inch]

|

[mm] | |

|

1/2

|

15 |

0.840

|

21.3

|

0.109

|

2.77 |

3/4 | 20 | 1.050 | 26.7 | 0.113 | 2.87 |

1 | 25 | 1.315 | 33.4 | 0.133 | 3.38 |

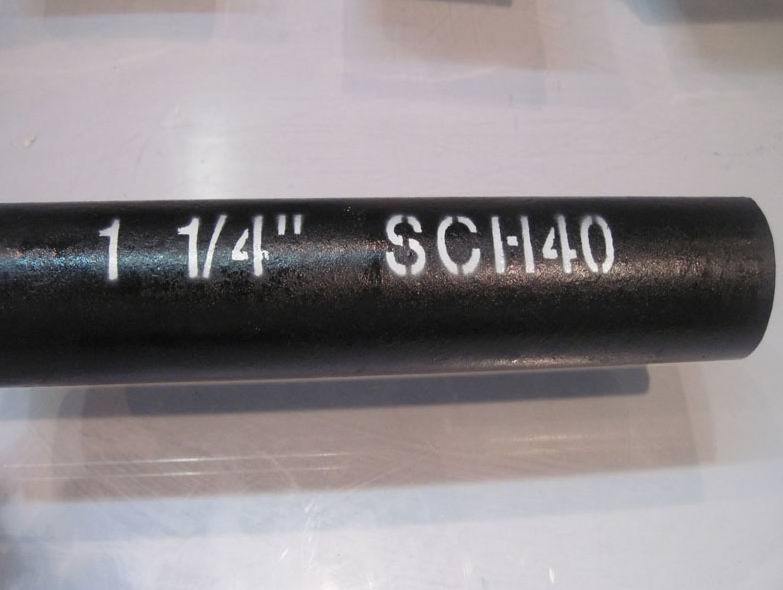

1 1/4 | 32 | 1.660 | 42.2 | 0.140 | 3.56 |

1 1/2 | 40 | 1.900 | 48.3 | 0.145 | 3.68 |

2 | 50 | 2.375 | 60.3 | 0.154 | 3.91 |

2 1/2 | 65 | 2.875 | 73 | 0.203 | 5.16 |

3 | 80 | 3.500 | 88.9 | 0.216 | 5.49 |

3 1/2 | 90 | 4.000 | 101.6 | 0.226 | 5.74 |

4 | 100 | 4.500 | 114.3 | 0.237 | 6.02 |

|

5

|

125 |

5.563

|

141.3

|

0.258

|

6.55 |

6 | 150 | 6.625 | 168.3 | 0.280 | 7.11 |

8 | 200 | 8.625 | 219.1 | 0.322 | 8.18 |

10 | 250 | 10.750 | 273.0 | 0.365 | 9.27 |

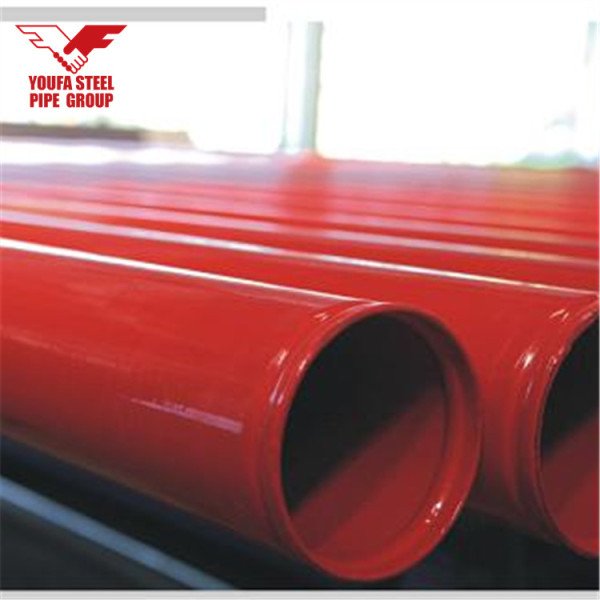

ASTMA 53 SCH 40 3/4 inch Metallic Sprinkler pipe Fire Protection System for construction

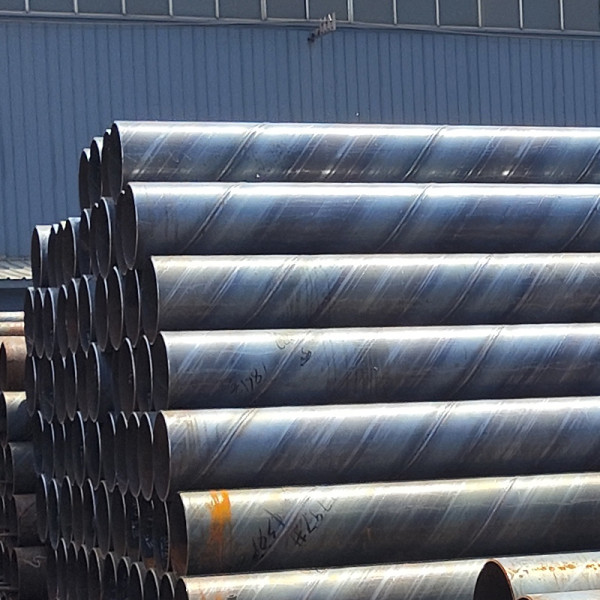

Sch40 spiral welded steel pipe is available in various diameter, ranging from 200mm to 900mm, used in conveying fluids and gas

SCHEDULE 40 CARBON STEEL pipe GI PIPE STANDARD LENGTH with factory price

Mild Seamless Steel Pipe /Tube Schedule 40/sch std Steel Pipe