en39 scaffolding tube 48.3 steel scaffolding pipe

- Model

- en39 scaffolding tube

Item specifics

- Standard

- BS1139 EN39 gb/t13793

- Zinc Coating

- 200-275g/m2

- Steel Grade

- S235 Q195 Q235 Q355

- Type

- ERW welded

- Surface

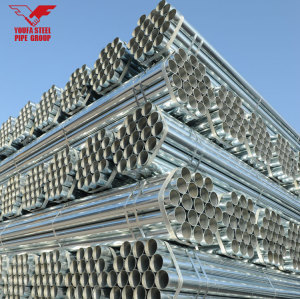

- Zinc coating galvanized

Review

Description

Scaffold Carbon Steel GI Pipe Detail Information

|

Size / Diameter

|

1-1/2" (48.3mm)

|

|

|

Wall thickness (W.T.)

|

Type 3 : 3.2mm

Type 4 : 4.0mm |

|

Length | 6.0M, 6.5M, 5.0M, 4.5M, 6.5M, cut into shorter length by customer's requirements | |

Certificates international standard | ISO 9000-2001,CE EN10219 certificate, BV certificate | |

Standards | EN39, BS1139, JIS3444, GB/T13793 | |

Materials | S235GT, S355, STK400, STK500, Q355 Q235 | |

|

Technique

|

ERW Welded

|

|

|

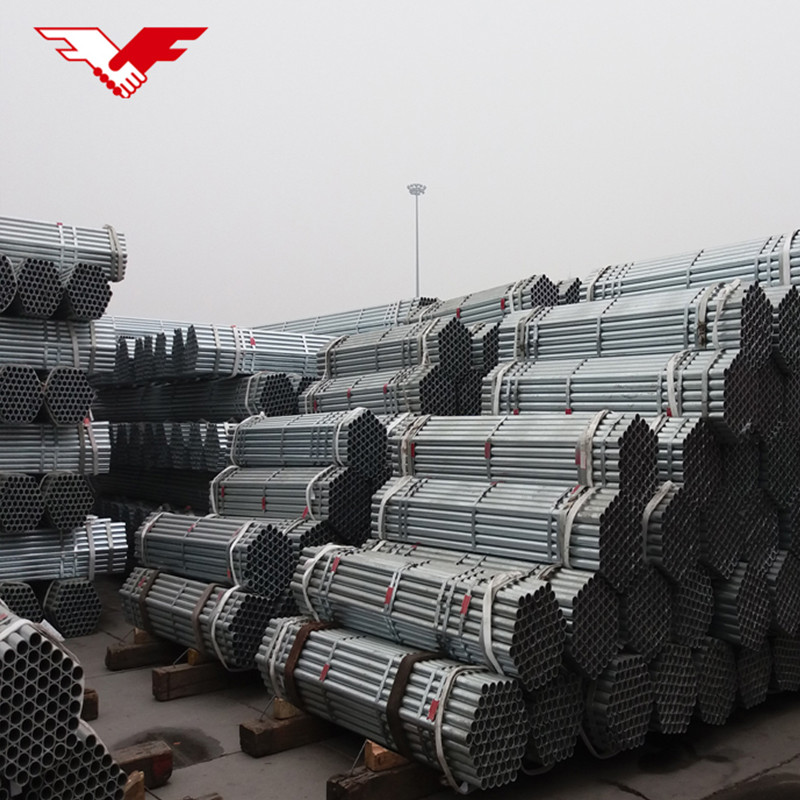

Packing

|

1. Packed by steel strips

2. Woven cloth with 7 slats

3. According to the requirements of customers |

|

Shipment | 1) Container: 26 tons per container for thick wall thickness pipe.

20"container: the max pipe length 5.85 m without caps;

40"container: the max pipe length 5.97 m in two rows.

2) Bulk carrier: no limits on pipe length. | |

Country of origin | China | |

Marking | As requested in PI, for example "EN39 YOUFA 48.3MM X 3.2MM / 4.0MM" | |

Scaffolding Pipe Steel Grade

|

EN39 S235GT

|

|||||||||

|

Chemical Composition %

|

Mechanical Properties |

||||||||

|

C (max.)

|

Si | Mn (max.) | P (max.) | S (max.) |

Al (min.)

|

Yield Strength(min.) MPa | Tensile Strength MPa |

Elongation (min.) %

|

|

|

0.20

|

≤0.05 % (range 1) (≤0.04 % if option 2 is specified) or ≥0.15 %≤0.25% (range 2) | 1.40 | 0.040 | 0.045 |

0.020

|

235 | 340-520 | 24 |

|

BS1139 S235 | |||||||||

C (max.) | Si (max.) | P (max.) | S (max.) | Ni (max.) | Yield Strength(min.)

MPa | Yield Strength(min.)

MPa | Elongation (min.) % | ||

0.20 | 0.30 For steel which is to be protected by hot dip galvanizing, the silicon content shall not exceed 0.05 %. | 0.05 | 0.05 | 0.009 For steel treated with aluminium, the nitrogen content may be increased to a maximum of 0.015 %. | 235 | 340-480 | 24 | ||

Customized Process Type for Scaffolding Pipe

1. Stamping / Embossing

The cost of embossing (the up one) is expensive than stamping (the bottom one). We usually choose stamping on the outside body of pipe. But for scaffold pipes, it is usually embossing.

Galvanized Steel Pipe Test and Quality Control

YOUFA Galvanized steel pipes cover one-third of the Chinese market

How does Youfa guarantee galvanized pipe quality ?

1. Youfa factories source their raw materials for manufacturing steel pipes from well-established and reputable Chinese enterprises such as HBIS, Shougang, Baotou Steel, Xintiangang, Jinxi Steel, and others.

2. Youfa Group has 4 labs with CNAS certificates in our own factories. We promise that before the goods leave the factory, there will be professional quality inspection personnels to conduct on-site inspections of materials, specifications, etc., and take pictures and archive them.

3. During the cargo transportation process, we take photos to record the loading status of the goods.

4. Youfa hot galvanized steel pipes are certified by CE, UL, ISO 9001, ISO 14001.

Youfa Brand Steel Pipe Production Range Details

|

Main Products

|

Size

|

Wall Thickness

|

Production Lines

|

Producing Capacity |

|

ERW steel pipe

|

1/2" -- 8"

|

1.5mm--10.0mm

|

13

|

1,000,000 tons per yesr |

|

Hot-dipped galvanized steel pipe

|

1/2" -- 8"

|

1.5mm--10.0mm

|

18

|

1,500,000 tons per year |

Square Rectangular steel pipe | 20x20--400x400mm,

20x40--400x600mm | 1.3mm--20mm | 10 | 800,000 tons per year |

Hot-dip galvanized

square / rectangular steel pipe | 20x20--200x200mm,

20x40--250x150mm | 1.5mm--7.5mm | 3 | 250,000 tons per year |

|

Oil casing pipe, SSAW steel pipe

|

219mm-2020mm

|

5.0mm--28mm

|

5

|

1,50,000 tons per year |

Steel-plastic complex

steel pipe | 1/2"--12" | 1.5mm--10.0mm | 9 | 100,000 tons per year |

ERW carbon steel pipe

Square and Rectangular steel pipe

Galvanized square steel pipe

Spiral welded steel pipe