API 5L Standard PSL1 and PSL2

- Share

- Issue Time

- May 28,2024

Summary

The API 5L standard specifies requirements for the manufacture of two product specification levels (PSL) of line pipe for use in the transportation of gas, water, and oil in the petroleum and natural gas industries. These two specification levels are PSL1 and PSL2, which have different requirements for various properties.

API 5L Standard aims to gas and water in oil and gas industry for reference, which is used for seamless steel pipe and welded steel pipe.

The API 5L standard specifies requirements for the manufacture of two product specification levels (PSL) of line pipe for use in the transportation of gas, water, and oil in the petroleum and natural gas industries. These two specification levels are PSL1 and PSL2. PSL is short for product specification level. PSL2 is a higher level of specification compared to PSL1, with differences not only in inspection requirements but also in chemical composition and mechanical performance requirements. When placing an order according to API 5L, it's necessary to specify the grade of steel and the product specification level, either PSL1 or PSL2. PSL2 has mandatory requirements for carbon equivalent, notch toughness, maximum yield strength, and tensile strength.

Chemical Composition

PSL1

Less stringent chemical composition requirements.

PSL2

Stricter controls on elements and their limits, including mandatory limits on the carbon equivalent (CE) to ensure better weldability and toughness.

Mechanical Properties

PSL1

Basic requirements for mechanical properties like yield strength, tensile strength, and elongation.

PSL2

More stringent and comprehensive requirements, including:

*Maximum Yield Strength: Specific upper limits to avoid excessive hardness.

*Tensile Strength: Defined range for better consistency in performance.

*Notch Toughness: Mandatory Charpy V-Notch impact testing to ensure the material can withstand harsh conditions and low temperatures.

Inspection and Testing Requirements

PSL1

Basic inspection and testing such as hydrostatic testing for pressure integrity.

PSL2

Enhanced inspection and testing, including:

*Non-Destructive Testing (NDT): Mandatory for all PSL2 pipes, ensuring no defects that could affect performance.

*Charpy Impact Test: Required to determine the material's toughness and ability to absorb energy during fracture.

API 5L Steel Pipe Ordering Information:

When placing an order for API 5L line pipe, it is essential to:

1. Types of pipes: Seamless (SMLS) steel pipes or Welded ( ERW , SSAW , LSAW ) steel pipes;

2. Specify the grade of steel (e.g., X42, X52);

3. Indicate the product specification level (PSL1 or PSL2);

4. Include any additional requirements based on the application (e.g., sour service, additional testing).

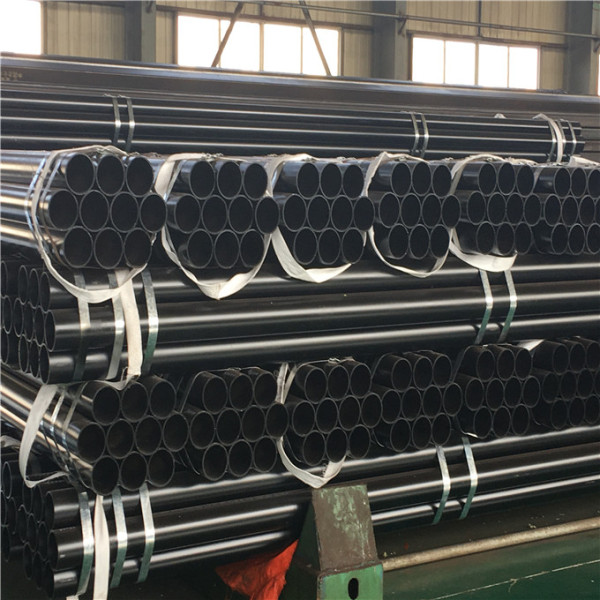

API 5L X52 od 219-3000mm piling steel pipes SSAW Spiral welded steel pipes for the line pipe of petroleum

Certified: API 5L, ISO

Surface Coating: Epoxy Coating / Colour Paint Coating / 3LPE Coating.

Support: OEM&ODM

API 5L is API which defines the standard for the dimension, physical, mechanical and chemical properties of the steel.

API seamless steel pipe used for petroleum pipeline