ASTM A795 Fire Pipe with grooved ends

Item specifics

- Technic Standard

- ASTM A53 , ASTM A795

- Pipe Length

- 5.8m, 6m, 6.4m, 7.3m, 19ft, 20ft, 21ft, 24ft

- Other surface finished

- painted red color RAL3000 , Galvanized and then painted red color, black color painted, epoxy coated, anti-rust oiled , or bare no surface treatment

- About surface finished

- the surface finished can be specified by customers

Review

Description

Fire Sprinkler Steel Pipe General Product Information

ASTM A795 is a standard specification for black and hot-dipped zinc-coated (galvanized) welded and seamless steel pipe for fire protection use. The pipe is intended for use in fire protection systems, and it is commonly used with grooved ends for easy installation.

Carbon steel pipe grooved ends allow for quick and secure connections using mechanical couplings, which are often used in fire protection systems for their reliability and ease of installation.

|

Commodity

|

Fire sprinkler ERW carbon steel pipes |

|

Usage | construction, building material, fire sprinkler steel pipeline | |

|

Size

|

1/2''-8'' (round hollow)

|

|

Wall thickness | 1.3mm-10mm | |

Length | 5.8m, 6m or cut into other length according to PI | |

Certificates international standard | ISO 9000-2001, UL certificate | |

Standards | ASTM A795, ASTM A53, GB/T3091, etc | |

|

Technique

|

Welded

|

|

Surface | Galvanized or Painted to prevent the rust | |

Pipe ends | Plain or threaded with sockets/coupling and plastic cap or grooved with caps | |

|

Packing

|

In bundles, or request.

|

|

Marking | As requested in PI, for example "UL LISTED YOUFA SCH10 / SCH40" | |

ASTM A795 ERW Carbon Steel Tube Standard Specifications Reference

NPS | DN | Outer Diameter(mm) | Schedule 10 | Schedule 40 | ||||

Wall Thickness (mm) |

Unit Weight (kg/m) | Test Pressure (kpa) | Wall Thickness

(mm) | Unit Weight

(kg/m) | Test Pressure (kpa) | |||

|

1/2"

|

15

|

21.3 |

-

|

- | - | 2.77 | 1.27 | 4800 |

|

3/4"

|

20

|

26.7 | 2.11 |

1.28 | 4800 | 2.87 | 1.69 | 4800 |

1" | 25 | 33.4 | 2.77 | 2.09 | 4800 | 3.38 | 2.50 | 4800 |

1-1/4" | 32 | 42.2 | 2.77 | 2.69 | 6900 | 3.56 | 3.39 | 6900 |

1-1/2" | 40 | 48.3 | 2.77 | 3.11 | 6900 | 3.68 | 4.05 | 6900 |

2" | 50 | 60.3 | 2.77 | 3.93 | 6900 | 3.91 | 5.45 | 6900 |

2-1/2" | 65 | 73 | 3.05 | 5.26 | 6900 | 5.16 | 8.64 | 6900 |

3" | 80 | 88.9 | 3.05 | 6.46 | 6900 | 5.49 | 11.29 | 6900 |

4" | 100 | 114.3 | 3.05 | 8.37 | 8300 | 6.02 | 16.09 | 8300 |

5" | 125 | 141.3 | 3.40 | 11.58 | 8300 | 6.55 | 21.79 | 8300 |

6" | 150 | 168.3 | 3.40 | 13.85 | 6900 | 7.11 | 28.29 | 8300 |

8" | 200 | 219.1 | 4.78 | 25.26 | 5500 | sch30 7.04 | 36.82 | 8300 |

10" | 250 | 273.1 | 4.78 | 31.62 | 4800 | sch30 7.8 | 51.05 | 6900 |

Pls don't hesitate to contact us if you need other sizes. | ||||||||

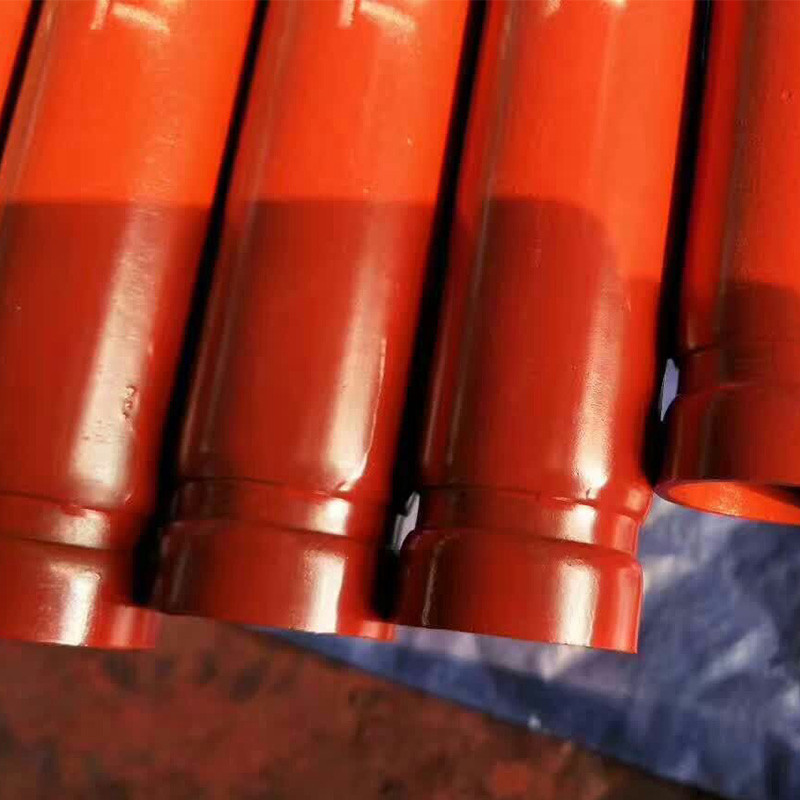

ERW Carbon Steel Fire Sprinkler Pipes Surface and Pipe Ends

Surface: Painted Ral3000 or other color

Pipe Ends: Grooved with caps

Surface: Zinc coated 30um or above

Pipe Ends: Grooved with caps

Surface: Zinc coated 30um or above

Pipe Ends: NPT threaded with coupling and cap

Surface: Painted Ral3000 or other color

Pipe Ends: NPT threaded with coupling and cap

ASTM A795 Fire Sprinkler Pipes Test and Quality Control

Chemical Composition |

for Type E (electric-resistance-welded pipe)

|

|||

|

C, Max, %

|

Mn, Max, % |

P, Max, %

|

S, Max, %

|

|

|

Grade A

|

0.25

|

0.95 |

0.035

|

0.035

|

|

Grade B

|

0.30

|

1.20 |

0.035

|

0.035

|

Mechanical Properties |

for thickness sch10 and sch40

|

||

|

Tensile strength, min [MPa]

|

Yield strength, min [MPa]

|

Elongation, min, %

|

|

|

Grade A

|

330

|

205

|

24

|

|

Grade B

|

415

|

240

|

24

|